Look at the post behind the link. There is a dark mode version.

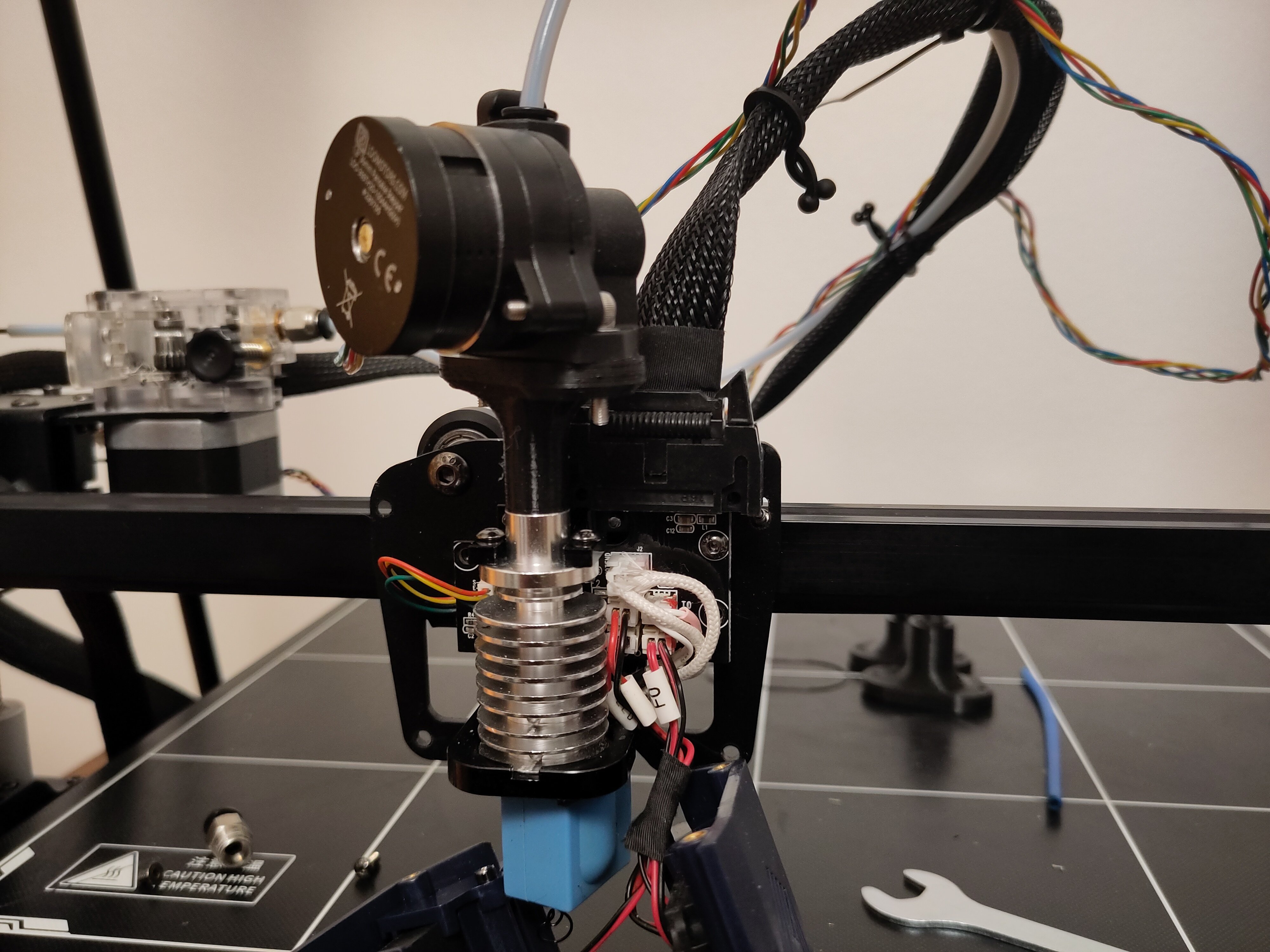

Did you measure that? Would be great if it was only fractions of a mm.

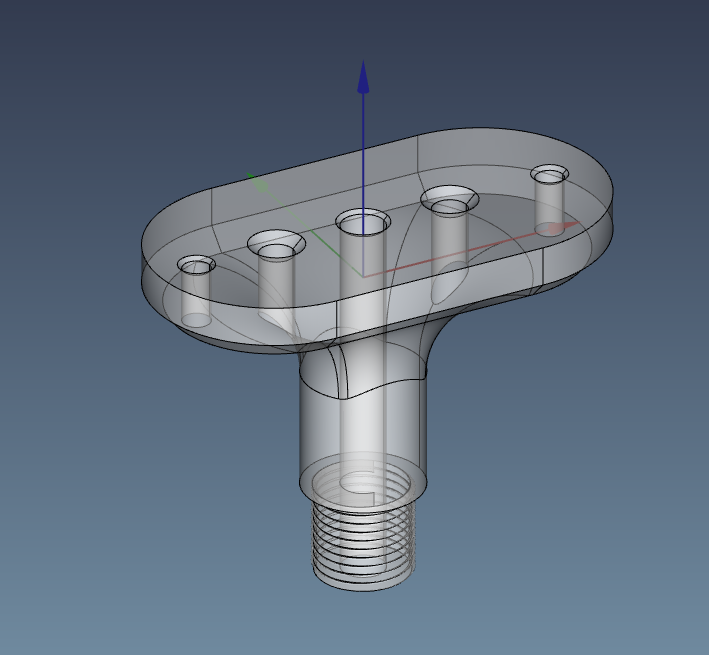

Would a larger inner diameter not cause the transmission of movement to be less direct due to bending and coiling inside the tube? This is probably mostly an issue in bowden systems

Yeah, very nice. It will be tough to bootstrap since you need a critical mass of people who ideally live close together so that it's cheap and quick enough to deliver the items in question.

I'll give it a try. Nothing to loose.

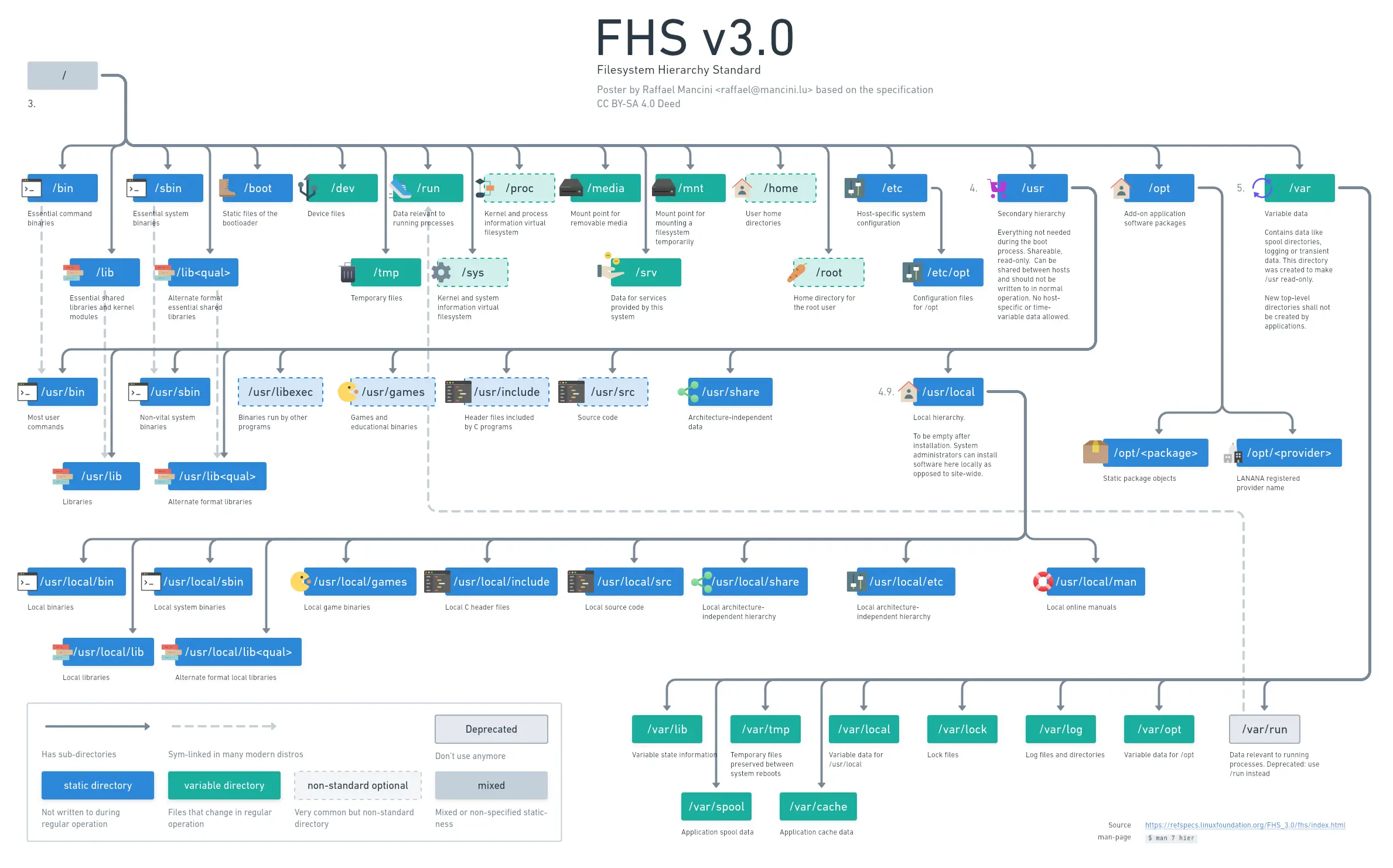

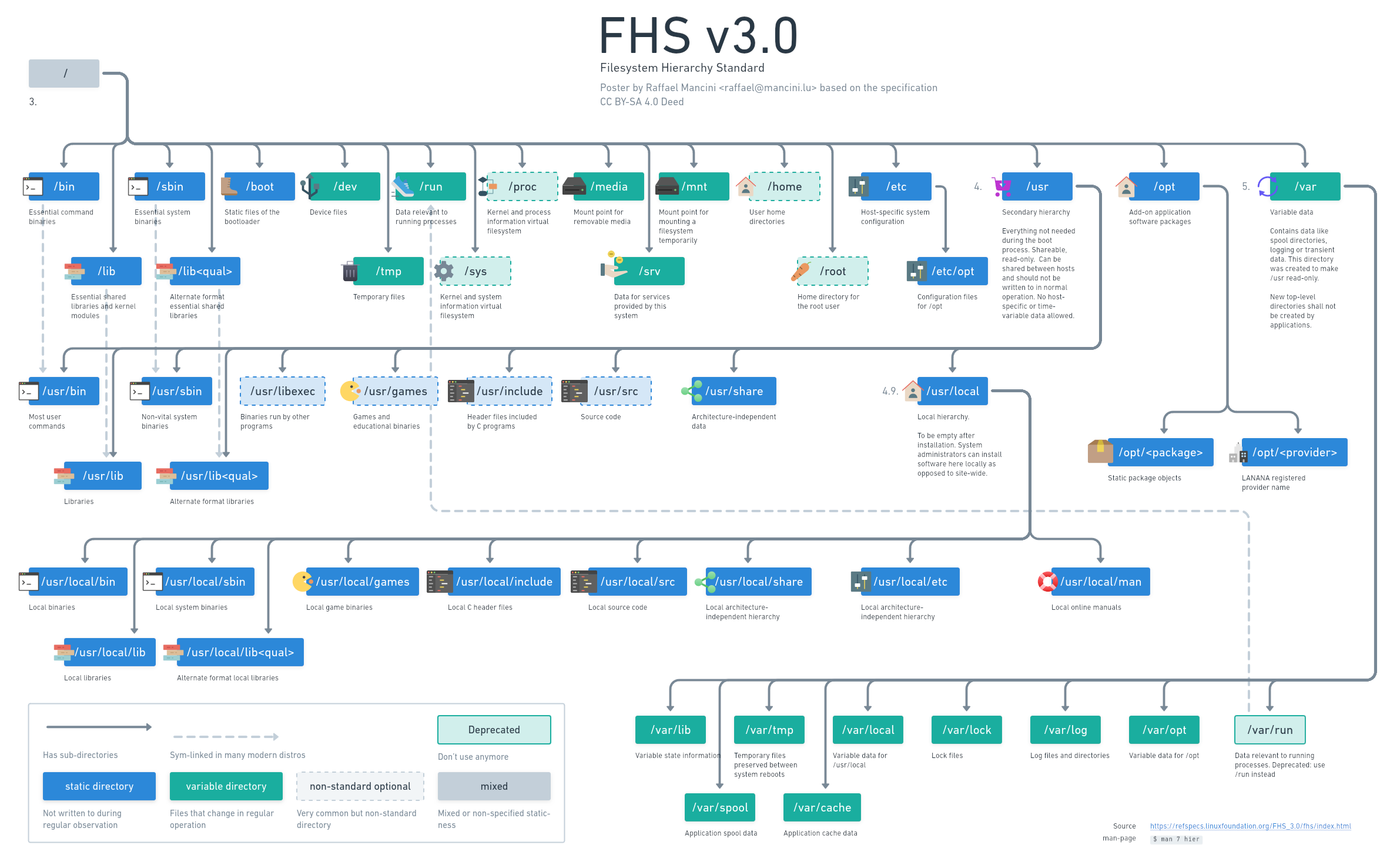

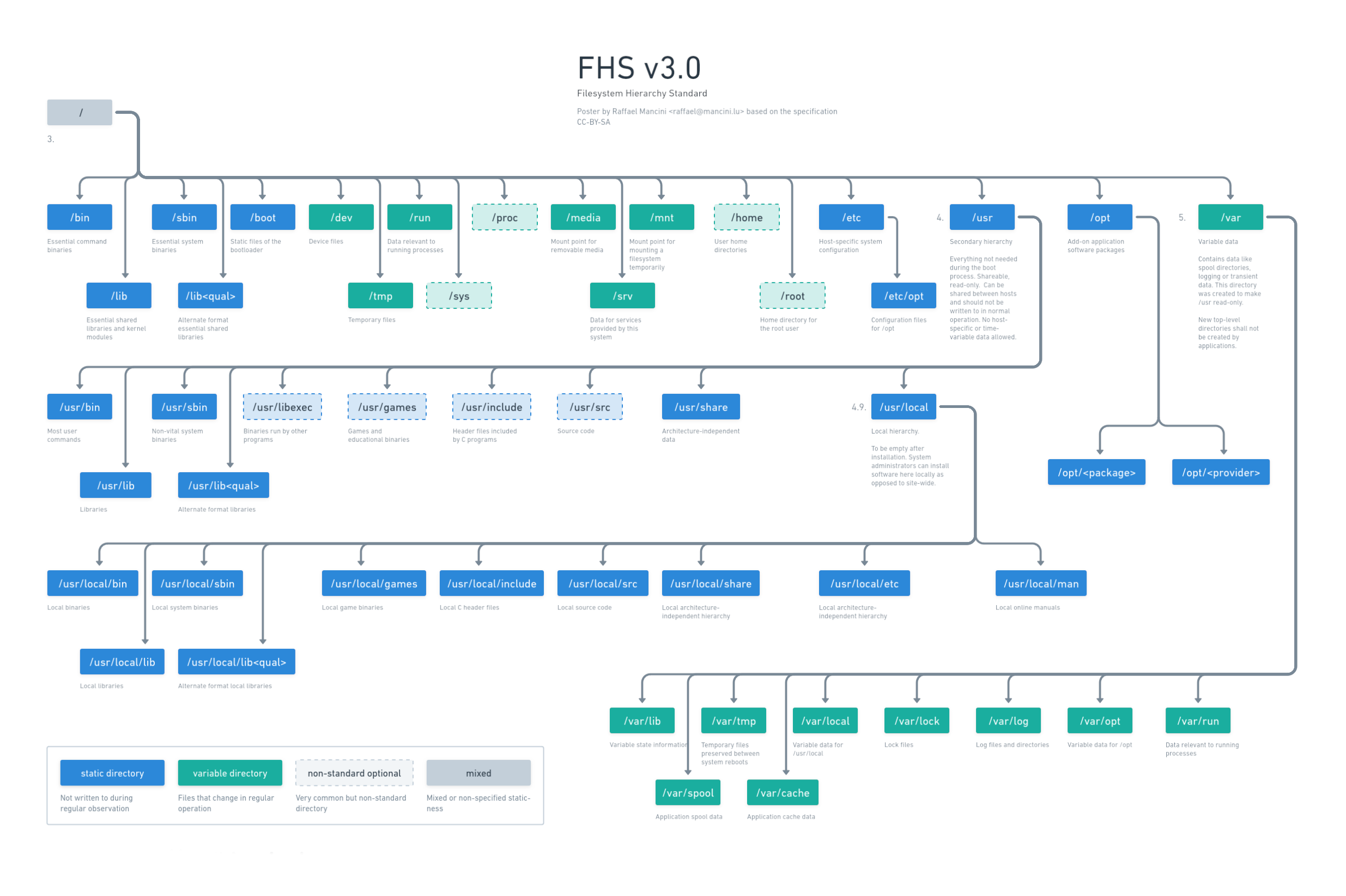

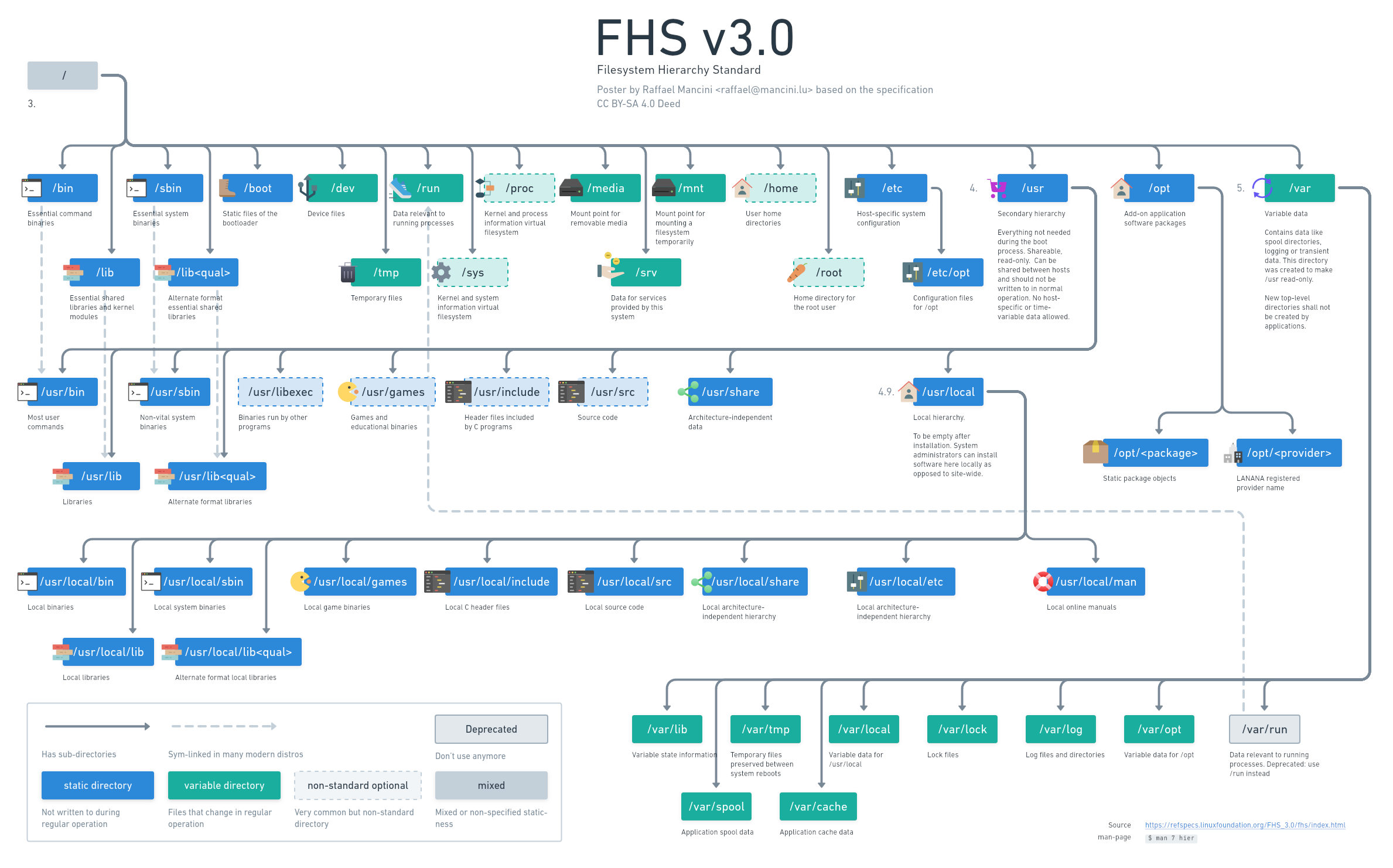

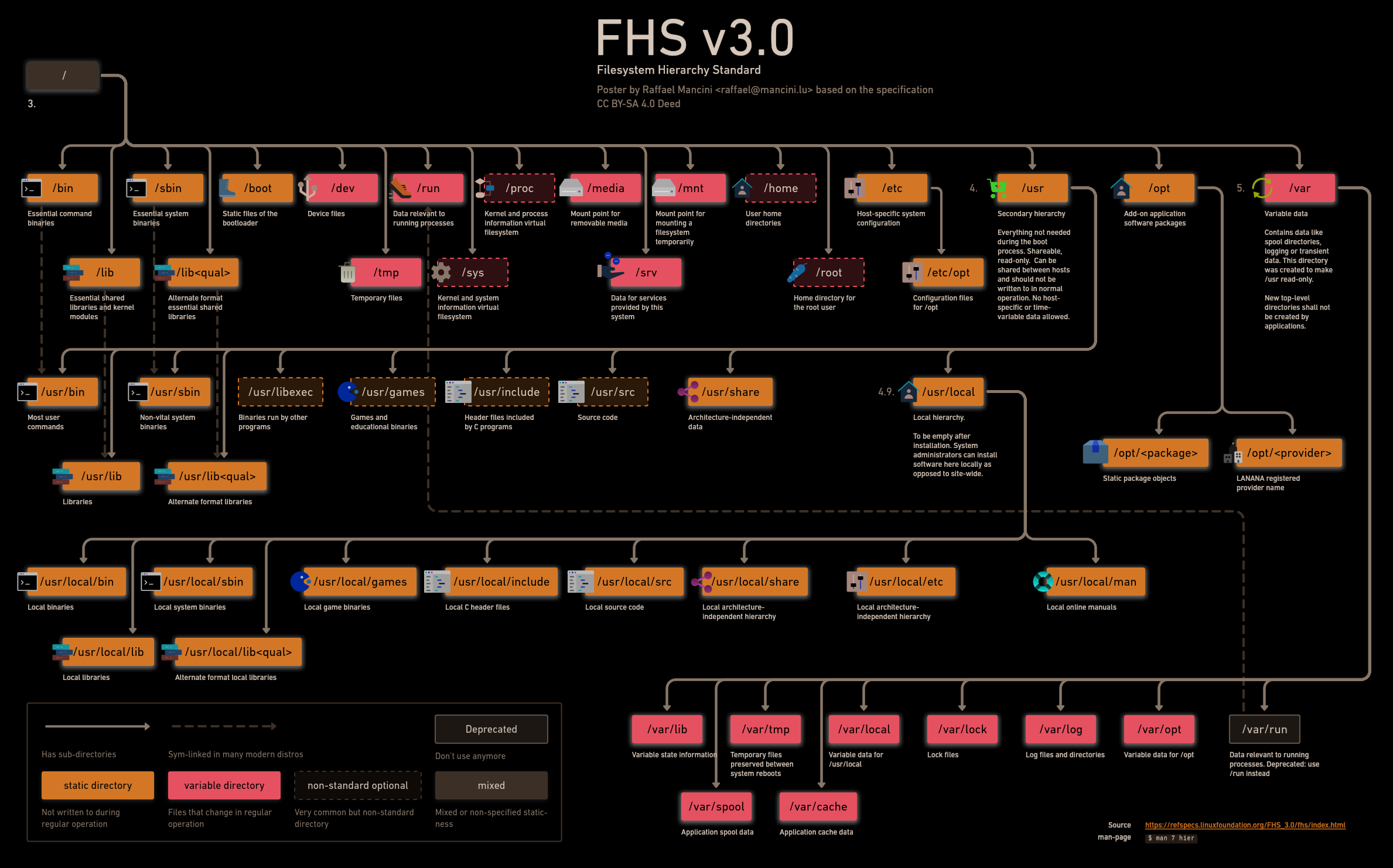

I've been using various GNU/Linux distro over the course of the last 20 years. When I started out, packages could never be too fresh and cutting edge. Nowadays I'm an admin and I administer way too many VMs. I dream of a system that I never need to update. While I know that's almost impossible if you want to be secure now might finally be the time I give slackware a try. I'm also old enough to be more curious about learning less but more in depth.

Me too

Libre office calc would do the trick also, every cell is a day for example

Why a gantt chart for a road trip though. There are not that many parallel things you usually do, no?

Interesting. I might have a look. Actually I don't have a problem with speed though. I spend most time not dealing with pip and pip-tools but reading docs, programming and fixing the weirdest bugs

Pip-tools!

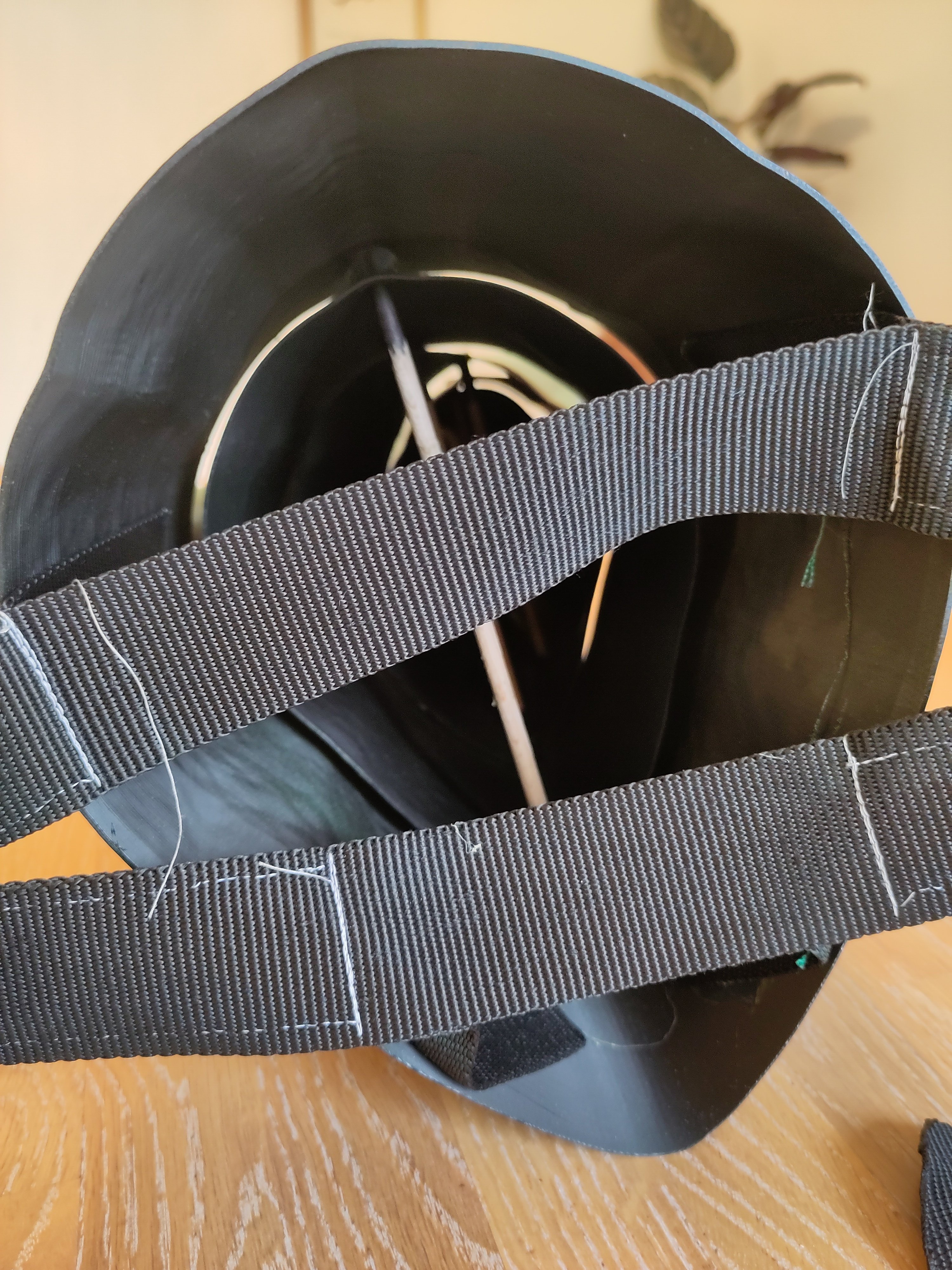

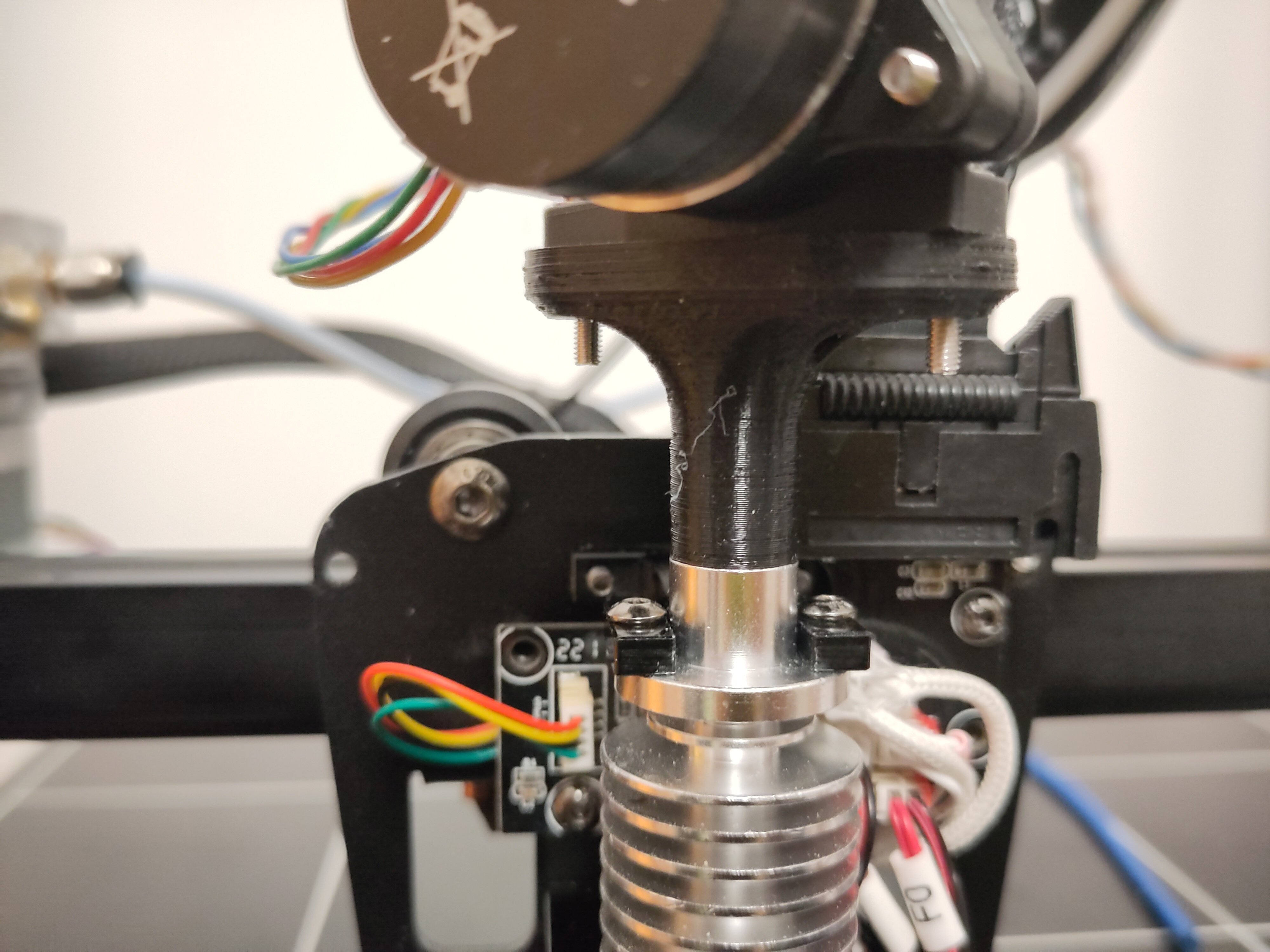

Sorry, I completely didn't read all of your comment. You're right about resistance but then again the filament won't need to touch the enclosing coil at a large surface. In the usual bowden tubes, you have a lot of contact surface between tube and filament but this would not need to be the case in the drying coil. In the end it would all depend on the application. I'm not interested in very high speed printing (yet) because my machines are all pretty slow :).